DIY GUIDE: WHAT IS A MITRE SAW

Level up your cutting capabilities! If you’re a weekend warrior who can be found in the workshop cutting timber for DIY projects, and you don’t own a Mitre Saw yet – you’re missing out!

Their flexibility, quick adjustability, and accuracy to make straight, mitre, bevel and compound cuts will save you time and effort. Mitre saws are stationary tools, meaning you can put it on your benchtop and take your timber to it. They have a larger blade size which means you can cut larger pieces and they’re easy to set up for repeated cuts. This tool is perfect if you need to cut decking boards to length, trim down skirting boards or shorten door frames and pretty much anything else that needs a perfectly straight cut or a join.

THE BASICS

A mitre saw has a rotating table and rear fence that allows for the blade to adjust to angles up to 45 degrees in a mitre cut. The tilting head gives you the ability cut up to 45 degrees in bevel mode and when you add a mitre cut and a bevel cut you get a nice compound mitre cut.

Mitre saws have different sized blades, and this is just as simple as the bigger the blade the wider and thicker the timber you can cut. When you add slide rails to a mitre saw you will be able to cut wider materials up to 300mm.

Typically, there are 3 main blade sizes; 210mm (8¼“), 254mm (10”) and 305mm (12”) so the best thing to do is work out what size timber you will be cutting for you project and decide on the blades size from there. Remember, the bigger the blade size the bigger the cutting capacity. You can find guide information on the packaging.

SLIDING VS NON-SLIDING

As you might have guessed from the name, the main additional feature in a sliding compound mitre saw are the inclusion of rails that allow the saw blade to slide back and forth as you cut. A sliding compound mitre saw can make all the cuts that a standard mitre saw does, but the sliding rail means that it can handle a much wider material than a standard non sliding mitre saw. If it’s likely that you will need to cut thick or wide materials, then it’s worth investing in the sliding feature. Common jobs that are likely to involve cutting through thick woods include:

- Cutting or preparing fence posts

- Cutting floorboards

- Timber widths more than 200m

- Creating rebates or channel cuts

CUT TYPES

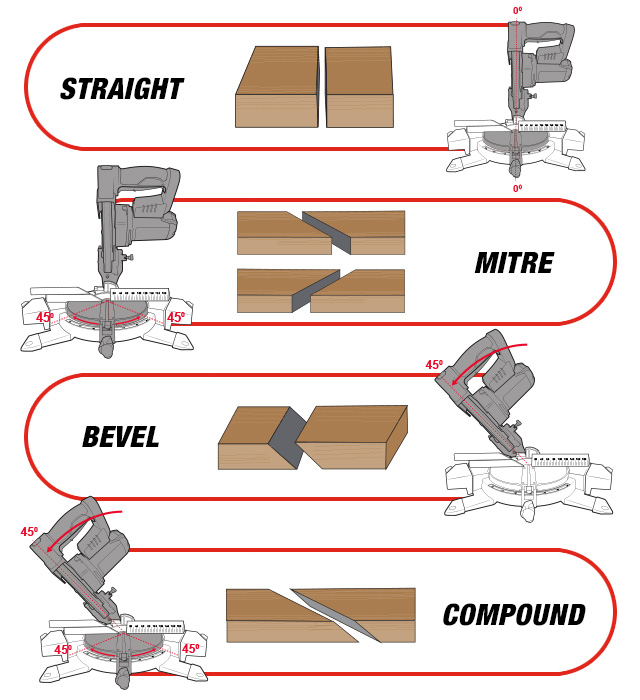

Straight or crosscut: Is a 90-degree cut across your piece of timber. This is a common cut when building furniture, framing up a wall or cutting down to size to make it easier to work with before making finish cuts.

Mitre cut: This is an angled cut on the face of the board and could be used for picture frames or cutting a door casing at the top corners.

Bevel cut: Also known as the ‘leaning cut’, the blade will lean left or right, and cut through the wood to create an angle cut along the edge of the board. This type of cut could be used for doing baseboards around a corner of a wall.

Compound cut: This cut is a combination of both bevel and mitre cuts. This type of cut is commonly used in roofing work, used when two pieces of wood meet but at different angles.